Effective inventory management is pivotal for any business aiming to maintain operational efficiency while minimizing costs. The ability to analyze inventory levels accurately can not only help in reducing excess inventory costs but also ensure a smooth supply chain. In today’s competitive marketplace, mastering the art of inventory level analysis is more critical than ever before.

Understanding Inventory Management Basics

Inventory management involves a systemized approach to ordering, storing, and using a company’s inventory. This includes raw materials, components, and finished products. At its core, inventory management seeks to have the right products in the right location at the right time.

Understanding the basics of inventory management is essential for businesses to keep inventory costs down while meeting customer demands. This involves balancing the needs of the customers against the cost of holding stock. It’s about making informed decisions that align with business objectives. Effective inventory management can lead to improved cash flow, reduced waste, and enhanced customer satisfaction, making it a critical component of operational success.

Moreover, the rise of e-commerce has transformed inventory management practices, necessitating a more agile approach to meet the fast-paced demands of online shoppers. Businesses must adapt to fluctuations in demand and ensure that they can fulfill orders promptly, which often requires sophisticated inventory tracking technologies and methodologies.

Key Concepts in Inventory Management

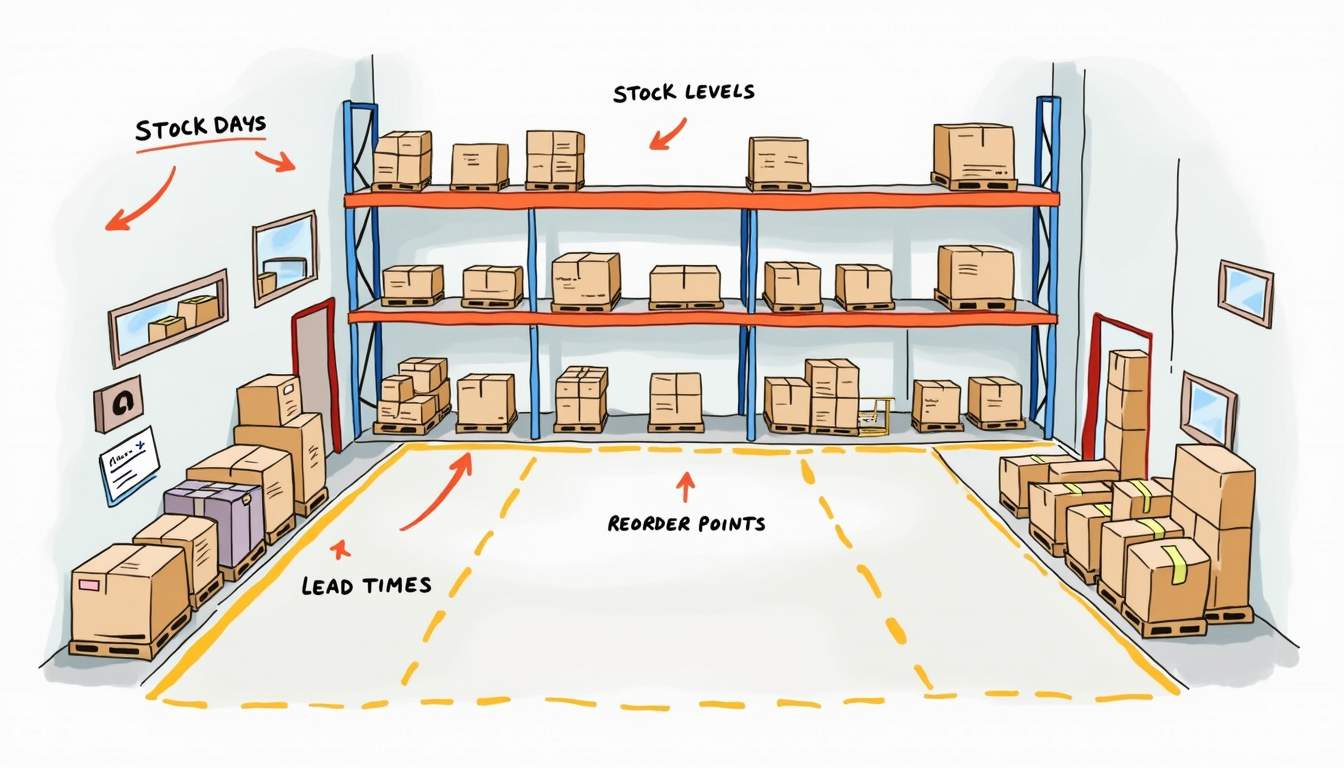

Several key concepts underpin effective inventory management. These include the reorder point, safety stock, and lead time. The reorder point is the level at which new stock should be ordered to avoid stockouts. Safety stock is the buffer inventory kept on hand to guard against uncertainty.

Lead time, the period between placing an order and receiving it, significantly influences inventory levels. Understanding these concepts helps managers develop strategies that keep inventory costs low while ensuring product availability. Additionally, concepts such as inventory turnover ratio, which measures how quickly inventory is sold and replaced over a period, provide valuable insights into the efficiency of inventory management practices. A high turnover rate often indicates effective inventory management, while a low rate may signal overstocking or insufficient sales strategies.

Types of Inventory Systems

There are various types of inventory systems used by businesses, with perpetual and periodic inventory systems being the most common. In a perpetual system, inventory records are updated continuously. This method allows real-time monitoring of inventory levels.

Conversely, the periodic inventory system updates inventory records at specified intervals. Each system has its advantages, and choosing the right one depends on the specific needs of the business. For instance, businesses with high transaction volumes may benefit from a perpetual system, as it provides immediate insights into stock levels and sales trends. In contrast, smaller businesses with less frequent inventory turnover might find a periodic system more manageable and cost-effective. Furthermore, advancements in technology have led to the emergence of hybrid systems that combine elements of both approaches, allowing businesses to tailor their inventory management strategies to their unique operational requirements.

The Importance of Inventory Analysis

Inventory analysis is a critical component of effective inventory management. It involves evaluating inventory data to identify patterns, optimize stock levels, and improve the overall efficiency of inventory processes.

Conducting regular inventory analysis helps businesses make data-driven decisions that can lead to significant cost reductions and improved customer satisfaction. By leveraging advanced analytics and technology, companies can gain deeper insights into their inventory dynamics, allowing them to stay ahead of market trends and customer demands.

Impact on Cost Reduction

One of the primary benefits of inventory analysis is its impact on cost reduction. By identifying slow-moving inventory and optimizing stock levels, businesses can reduce holding costs and improve cash flow.

Additionally, analyzing inventory allows for better demand forecasting, resulting in fewer stockouts and overstock situations. This helps in minimizing the costs associated with excess inventory or lost sales opportunities. Furthermore, inventory analysis can reveal opportunities for bulk purchasing or negotiating better terms with suppliers, ultimately leading to lower procurement costs and enhanced profitability.

Enhancing Operational Efficiency

Inventory analysis contributes to enhancing operational efficiency by providing insights into the supply chain process. Understanding the flow of inventory helps in identifying bottlenecks and inefficiencies that can be addressed.

This, in turn, leads to improved production planning and scheduling, ultimately boosting the overall productivity of the organization. Moreover, a thorough inventory analysis can facilitate better alignment between departments, such as sales and procurement, ensuring that everyone is on the same page regarding stock levels and availability. This collaborative approach not only streamlines operations but also fosters a culture of accountability and responsiveness within the organization.

In addition, implementing inventory analysis tools can empower businesses to adopt just-in-time (JIT) inventory practices, which minimize waste and reduce the need for large storage spaces. By maintaining optimal inventory levels, companies can respond more swiftly to changes in consumer preferences, thereby enhancing their competitive edge in the marketplace.

Methods for Analyzing Inventory Levels

Several methods can be employed to analyze inventory levels effectively. Each method offers unique advantages and can be chosen based on the business’s objectives and needs.

ABC Analysis

ABC Analysis is a method that categorizes inventory into three groups based on importance. Group A represents high-value items with low frequency of sales, Group B includes moderate value items with a moderate frequency of sales, and Group C consists of low-value items with high frequency of sales.

This method helps prioritize inventory management efforts, ensuring that resources are focused on the most critical items that contribute significantly to the company’s bottom line. By implementing ABC Analysis, businesses can streamline their inventory processes, reduce excess stock, and enhance cash flow management. Additionally, this method allows for more targeted marketing strategies, as companies can focus promotional efforts on high-value items that drive revenue, while also keeping a close eye on the turnover rates of lower-value items to prevent obsolescence.

Economic Order Quantity (EOQ)

The Economic Order Quantity (EOQ) model helps determine the optimal order quantity that minimizes total inventory costs. It considers both holding costs and ordering costs to find an ideal balance.

By calculating EOQ, businesses can reduce the total cost of inventory by avoiding overordering and underordering. This model is particularly useful for companies with consistent demand patterns. Moreover, EOQ can be adjusted to account for fluctuations in demand or changes in supplier lead times, making it a flexible tool for inventory management. Companies can also integrate EOQ with inventory management software to automate calculations, ensuring that they are always operating at peak efficiency and can quickly adapt to market changes without incurring unnecessary costs.

Just-In-Time (JIT) Inventory

Just-In-Time (JIT) inventory management is a strategy that aims to decrease waste by receiving goods only as they are needed for production. This reduces inventory holding costs and increases efficiency.

JIT requires precision and commitment from all parties involved, including suppliers and manufacturers, to ensure that the necessary materials are available exactly when needed. The implementation of JIT can lead to significant improvements in production flow and responsiveness to customer demand, as it minimizes the risk of overproduction and stockouts. However, it also necessitates a robust supply chain management system and strong relationships with suppliers to mitigate risks associated with delays or disruptions. Companies adopting JIT must invest in technology and communication systems to monitor inventory levels in real-time, enabling them to respond swiftly to any changes in demand or supply chain issues, thus maintaining operational continuity and customer satisfaction.

Tools and Technologies for Inventory Analysis

In today’s digital age, various tools and technologies can aid businesses in conducting detailed inventory analysis. These tools not only simplify the process but also provide valuable insights that can drive strategic decision-making.

Inventory Management Software

Inventory management software offers a comprehensive solution for tracking inventory levels, orders, sales, and deliveries. These systems automate much of the inventory management process, reducing human error and saving time.

Advanced features, such as real-time inventory tracking and demand forecasting, enable businesses to optimize their inventory management strategy, making it easier to adapt to changing market demands.

Data Analytics and Reporting Tools

Data analytics and reporting tools are invaluable for analyzing inventory data and turning it into actionable insights. These tools provide detailed reports and visualizations that can help businesses understand inventory trends and performance metrics.

By leveraging data analytics, companies can make informed decisions regarding inventory purchasing and management, ultimately leading to cost reductions and improved efficiency.

Strategies for Effective Cost Reduction

Implementing effective cost reduction strategies is crucial for improving profitability and ensuring sustainability in a competitive market. By focusing on inventory-related cost savings, businesses can achieve substantial financial gains.

Optimizing Stock Levels

One of the most effective ways to reduce inventory costs is by optimizing stock levels. This involves managing inventory to match demand patterns accurately, minimizing excess stock and reducing stockouts.

Effective inventory optimization requires a deep understanding of customer demand, market trends, and supplier capabilities. By aligning these factors, businesses can improve their inventory turnover rate and reduce carrying costs.

Reducing Holding Costs

Holding costs, which include storage, insurance, and depreciation expenses, can significantly impact a company’s bottom line. Implementing strategies to reduce these costs is essential for effective cost management.

Businesses can lower holding costs by consolidating storage facilities, optimizing warehouse space, and improving inventory accuracy to avoid unnecessary stock.

Streamlining Supply Chain Processes

Streamlining supply chain processes can lead to substantial cost savings by improving efficiency and reducing waste. Efficient supply chain management ensures that goods move smoothly from suppliers to customers without unnecessary delays or costs.

This involves adopting best practices such as vendor-managed inventory, just-in-time deliveries, and collaborative planning with suppliers and distributors. By refining these processes, businesses can enhance their competitive edge and improve their profitability.

Maximize Your Hotel’s Efficiency with Prosper Hotels

Understanding and optimizing your inventory levels is just the beginning. At Prosper Hotels, we take a holistic approach to enhance your hotel’s performance. From revenue management to digital marketing and group housing services, our seasoned experts are ready to elevate your hotel’s operations. Embrace the opportunity to drive revenue growth and empower your team with Prosper Hotels. Learn More about how we can support your journey towards greater efficiency and profitability.

Drive More Hotel Revenue

Through Untapped Strategies

Drive More Hotel Revenue

Through Untapped Strategies